Page 99 - Çevre Şehir İklim İngilizce - Sayı 2

P. 99

Burcu Hiçyılmaz - Sedat Alataş - Etem Karakaya

importance and potential of material efficiency in terms of mitigation policies,

respectively. The third part investigates the scope of the product life cycle and

the material strategies suitable for each stage, while the fourth part evaluates

and discusses the findings and concludes.

1. Industry, Mitigation Options and Material Efficiency

a. Industrial Emissions

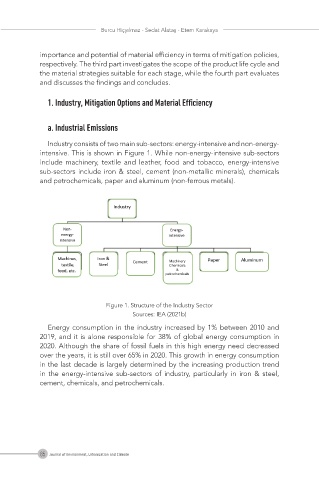

Industry consists of two main sub-sectors: energy-intensive and non-energy-

intensive. This is shown in Figure 1. While non-energy-intensive sub-sectors

include machinery, textile and leather, food and tobacco, energy-intensive

sub-sectors include iron & steel, cement (non-metallic minerals), chemicals

and petrochemicals, paper and aluminum (non-ferrous metals).

Machinery

Chemicals

&

petrochemicals

Figure 1. Structure of the Industry Sector

Sources: IEA (2021b)

Energy consumption in the industry increased by 1% between 2010 and

2019, and it is alone responsible for 38% of global energy consumption in

2020. Although the share of fossil fuels in this high energy need decreased

over the years, it is still over 65% in 2020. This growth in energy consumption

in the last decade is largely determined by the increasing production trend

in the energy-intensive sub-sectors of industry, particularly in iron & steel,

cement, chemicals, and petrochemicals.

85 Journal of Environment, Urbanization and Climate